What is Job Safety?

Job Safety is a component of TWI that provides a systematic approach to identifying and eliminating the conditions that lead to safety incidents. Not one of the original TWI programs developed during WWII, it was developed by the Japanese later and brought back to the U.S. by Pat Graupp of the TWI Institute (formerly of Sanyo). The belief of JS is that safety incidents don’t just happen, they are caused by the things – parts and materials, facilities, tools and machines, work methods or layout, and the environment – or by people due to their mental or physical state, work attitudes and methods, use of personal protective gear, and level of training or by the timing and environment of the work itself. JS teaches the leader to analyze these factors to spot and eliminate the causes of safety incidents before they happen. Like the other TWI programs, it is taught five two-hour sessions using a similar 4-step method captured on a pocket card.

The Causal Chain of Events

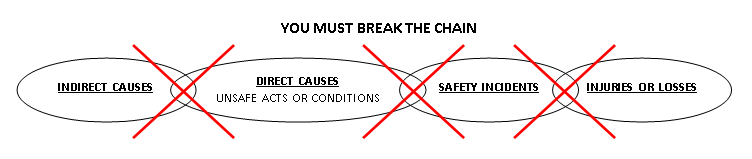

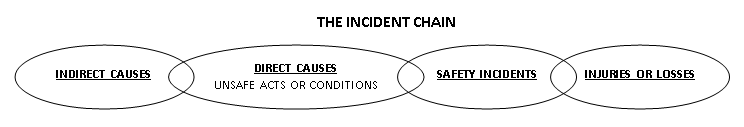

Job Safety takes the approach that all safety incidents have direct and indirect causes; accidents don’t just happen. Indirect causes can be the physical or emotional conditions that could allow unsafe acts to occur or the can be individual inadequacies caused by a poor work environment or social conditions. Some indirect causes could be the a culture of inattention or indifference to safety policies, inadequate leadership, excessive work or physical arrangement or orderliness of the work place. Direct causes are the unsafe acts or conditions that directly cause the safety incident. They include poor footing or position, errors in operation, or lack of safety devices. Direct causes result in safety incidents. A safety incident is where an act or condition causes or has the potential to cause injury or loss. Often incidents that do not result in an injury or loss are called ‘near misses,’ but we all know that statistically with an increase in near misses will eventually result in an injury or loss.

The objective of Job Safety is to train the leaders of the organization to proactively search for the direct and indirect causes and eliminate them before they become a safety incident, injury or loss. To break the chain of events, leaders should be checking the situation, environment, people and things to spot any direct or indirect causes and then take measures to eliminate them. If the chain can be broken anywhere along it’s length, then incidents, injuries and losses can be stopped.

The 4-Step JS Method

JOB SAFETY POCKET CARD

The meaning of safety is to consider measures and take action BEFORE a safety incident. It is NOT to handle the aftermath.

Step 1 – Spot the Causes of Danger

- Check the situation. Check the record. Talk to people.

- Consider both things and people.

- Check regulations and standards.

- Always be aware.

- Foresee risks of incidents and injuries

Dig down deep

Step 2 – Decide on the Countermeasures

- Fit the causes together; consider their bearings on each other.

- Ask people who have detailed knowledge.

- Think of several countermeasures.

- Make sure of alignment with policies, regulations and standards.

- Decide on back-up measures, too.

Are you yourself the cause?

Step 3 – Enforce Countermeasures

- Can you handle this yourself?

- Do you need support from your supervisor?

- Whose cooperation should you get?

Put into effect immediately

Step 4 – Check Results

- Check and check again.

- Was it carried out for certain?

- Were the causes eliminated?

Have any new causes arisen?

Safety Incidents Are Caused

Break the Chain

Things:

- Parts and Materials

- Facilities, Machines and Tools

- Work Methods and Layout

- Dangerous and Harmful Articles

- Environment

- State

- Placement

- Usage

People:

- Capabilities

- Mental and Physical State

- Work Attitudes and Methods

- Use of Personal Protective Equipment

- Handling of Tools

- Human Relations

- Doesn’t Know

- Cannot Do

- Doesn’t Care

- Doesn’t Do

Contact:

- How about timing?

Environment:

- Proper Housekeeping

- Scrupulous Inspection and Maintenance

- Standard Operating Procedures

A perfect safety record is not a record of fate; it is a record of our efforts as leaders

Respect for People – Study the Cause

The JS 4-Step Method is captured on the front side of the JS Pocket Card. Step 1 – Spot the Causes of Danger – helps the leader to analyze his work area, both people and things, to identify the possible direct and indirect causes of unsafe acts or conditions. This step and the 4-step method in general are designed to be proactive. After systematically and routinely identifying possible unsafe conditions and actions in step 1, the leader can then develop and implement countermeasures in step 2 – Decide on Countermeasures. These countermeasures should break the chain of causation preventing a safety incident, injury or loss. In Step 3 – Enforce Countermeasures –the leader implements what has been developed in step 2. The subheadings help the leader think through and then implement the preventive actions. Lastly, in Step 4 – Check Results, the leader checks to make sure that the implemented countermeasures do break the chain of causation and that the possibility of a safety incident has been prevented.

The flip side of the JS Pocket Card lists many of the areas to look at when spotting the direct and indirect causes of safety incidents. The leader needs to look at things in his workplace which includes the environment, work methods, machines and tools, and the parts and materials. He also must look at the people taking care to note any potential causes from their capabilities, state of mind, work attitudes, use of personal protective gear, and level of training. The card reminds the leader that timing is also critical. Incidents are much more likely when two things or people are moving, than when just one is moving. Lastly, leaders must routinely scan the environment checking for proper housekeeping and organization, maintenance is being performed , and that people are following their standard work. Good safety records don’t happen by luck. The hard work of leaders results in good safety records.

Benefits

The benefits from implementing Job Safety can permeate all facets of your operation. Your safety performance will be directly improved resulting in:

- Fewer injuries

- Fewer lost work days

- Lower number of recordable incidents

- Lower workman’s comp claims and premiums

There are additional benefits that a strong JS program can bring:

- Higher morale

- Greater productivity

- Greater employee involvement

- Reduced costs

- Generally safer place to work

In the end, the benefits you receive will not be by accident, but by the hard work of your leaders identifying and resolving the direct and indirect causes of safety incidents in your operations.